Circuit Board Tracking

We were hired by a local electronics company to help integrate Intermec CN70E Mobile computers with RFID capability into a CIM (Computer Integrated Manufacturing) environment. The customer developed their CIM system and a complex set of web services using Java. We were asked to build a web services client using vb.NET. We worked closely with the company’s CIM team to specify and develop the software.

The application tracks and validates circuit boards as they move through each operation of the manufacturing process. Each circuit board has a bar code and a small RFID chip attached to it, with both containing the ID number of the circuit board.

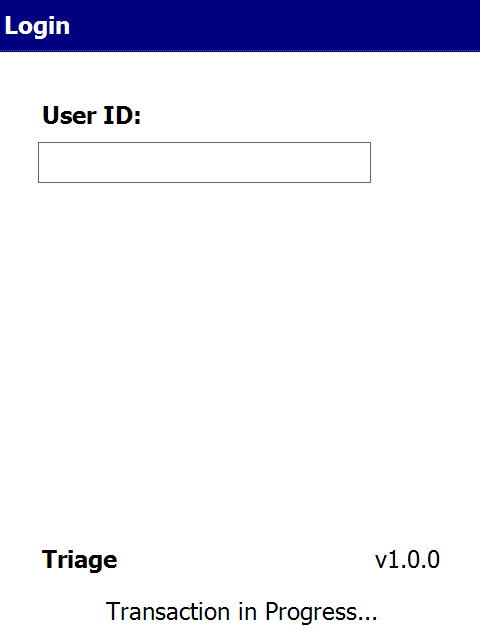

Only specific users can use the application, so the login screen validates the users as they log in.

The Login screen:

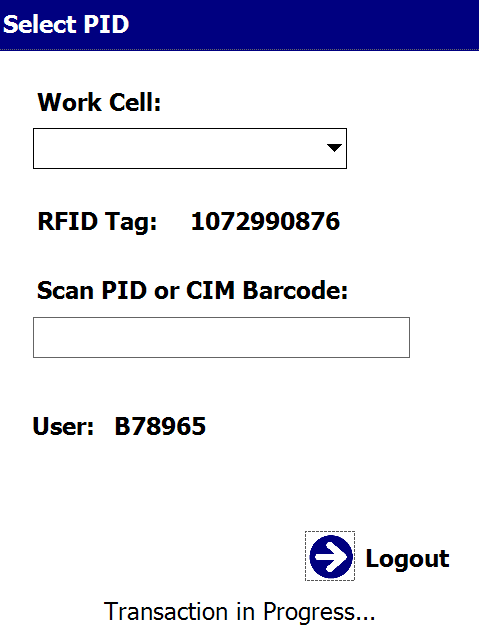

Once the user logs in they can scan a bar code from shop floor paperwork or the circuit board’s bar code or RFID tag to validate the order number/ production ID number and retrieve specific process information.

The Order / Production ID screen:

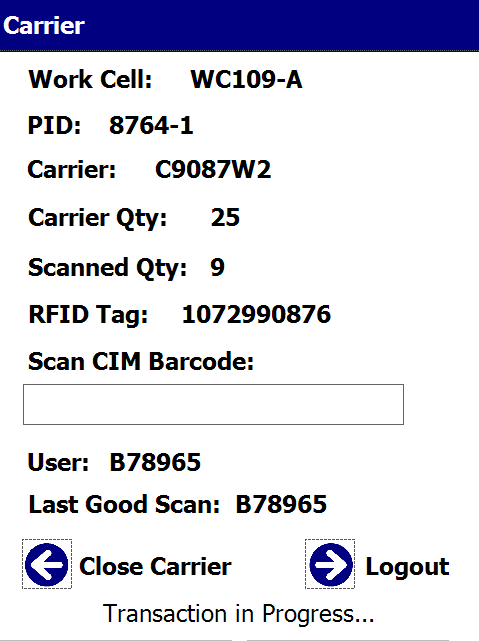

Once the order is validated, the manufacturing operations are determined by the CIM system. The program determines if the circuit boards are required to be scanned in to a carrier rack for the next operation or if they are individually moved to the next work cell.

The Carrier Rack screen:

The program knows how many boards a carrier rack can hold, so it will close the transaction automatically once a rack has reached its capacity. The user can close the operation manually at any time.

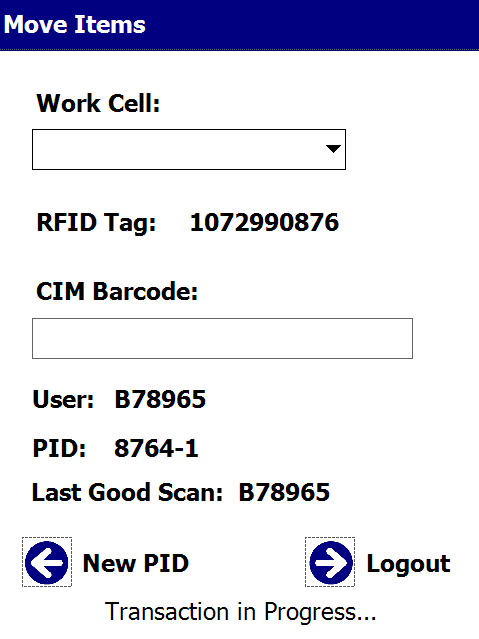

The Move screen:

This transaction moves an item to the next work cell when a carrier rack is not required.

The web services validate every transaction scan or RFID tag read and return a “Go” / “No Go” status and message, which prevents carrier racks or boards from being moved to the wrong work cell.

Conclusion

The program went into production and quickly increased the accuracy for locating orders and items in the manufacturing process.